Did you know cotton makes up 90% of all natural fibers in textiles? This fact highlights cotton’s popularity and its long journey from simple fiber to complex fabric. The textile world is a mix of art and technology, telling stories through our fabrics. Every step, from fiber to fabric, uses special techniques and new ideas.

As we explore this industry, we’ll see how these steps help make the textiles we use daily.

Key Takeaways

- The textile manufacturing process has five main steps: gathering fiber, preparing it, spinning it into thread, processing thread into cloth, and finishing the cloth.

- Cotton is the most used natural fiber, making up 90% of all natural fibers in textiles.

- Weaving creates fabric by crossing vertical warp yarns with horizontal weft yarns.

- Dyeing fabrics is a mix of art and science to get bright colors.

- Modern spinning, like ring spinning, makes yarn production better and more efficient.

- Fabric finishing, such as calendaring and mercerization, makes the fabric look and feel better.

The Importance of Textile Manufacturing

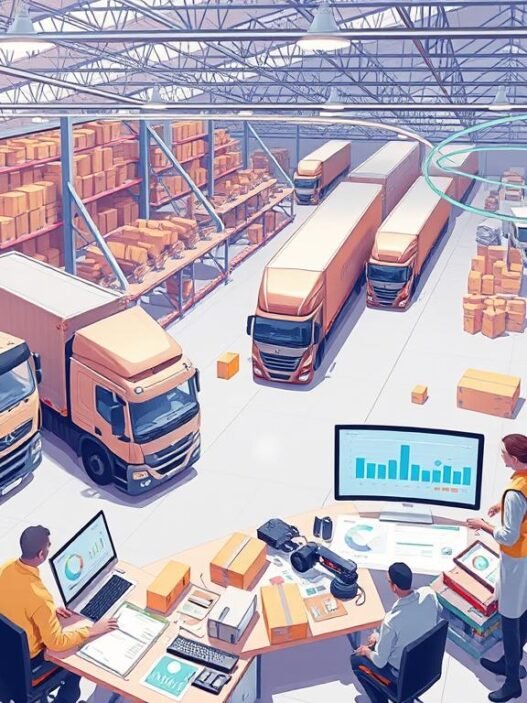

The textile industry is key in meeting basic human needs like clothes and shelter. It’s more than just providing these necessities; it’s a big part of the global economy. Every year, the textile economy adds billions of dollars, making it a major economic force in many countries.

Textiles create a lot of jobs worldwide, with millions working in this field. It supports farmers, manufacturers, designers, marketers, and retailers. This shows how the textile industry affects many jobs, helping communities and economies grow.

Innovation in textiles connects old traditions with new tech. This industry faces challenges like sustainability, but it can adapt and stay important. By solving these problems, textiles can keep meeting our needs while also protecting the environment.

Understanding Fiber Types

The textile industry uses two main types of fibers: natural and synthetic. Each type has special properties that affect how textiles look and work. Knowing about these fibers helps us choose materials wisely, especially when we think about the planet.

Natural Fibers: Building Blocks of Fabric

Natural fibers come from plants and animals. They’ve been used to make textiles for centuries. Here are some common ones:

- Cotton: It’s soft and versatile, but not very stretchy.

- Linen: This is the strongest plant fiber. It’s good at soaking up water and looks shiny.

- Wool: From sheep, wool is stretchy and keeps moisture away. It also fights static.

- Silk: Made by silkworms, silk feels luxurious and looks bright. But it’s not very stretchy.

- Jute: It’s biodegradable and cheap, but not very strong.

Synthetic Fibers: Innovation in Textiles

Synthetic fibers have changed the textile world. They offer benefits that natural fibers can’t. They’re made from oil and include:

- Polyester: It’s light, strong, and doesn’t wrinkle easily.

- Nylon: This fiber is very strong and stretchy. It’s used in clothes and industrial stuff.

- Acrylic: It’s soft and strong when mixed with other fibers. You find it in clothes and carpets.

- Rayon: Made from plants, rayon is soft and soaks up water well. But it’s not as strong as natural fibers.

Synthetic fibers are getting better, but they also have environmental downsides. This makes people want more eco-friendly ways to make textiles.

| Fiber Type | Source | Key Properties | Sustainability Considerations |

|---|---|---|---|

| Cotton | Plant | Soft, durable, absorbent | Water-intensive cultivation |

| Linen | Plant | Strong, absorbent, lustrous | Lower water usage, biodegradable |

| Wool | Animal | Elastic, moisture-wicking | Animal husbandry impact |

| Silk | Animal | Luxurious, smooth | Ethical concerns in production |

| Polyester | Synthetic | Lightweight, durable, wrinkle-resistant | Derived from fossil fuels |

| Nylon | Synthetic | Strong, elastic | Environmental impact of production |

| Acrylic | Synthetic | Lightweight, soft | Non-biodegradable |

| Rayon | Cellulosic | Soft, highly absorbent | Processing affects sustainability |

Knowing about these fibers helps us make choices that are good for both the planet and our clothes.

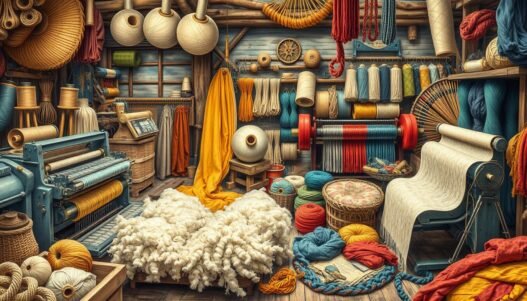

The Process of Fiber Production

Fiber production is key in making textiles. It uses different fiber production methods for each type of fiber. These methods greatly impact the quality and how sustainable the materials are.

Natural fibers like cotton and silk need a lot of farming. Cotton, for example, uses a lot of water and pesticides. But, if farming is done in a sustainable way, it can be better.

Animal fibers, such as wool, also need special farming. This helps improve wool quality and takes care of the animals.

Synthetic fibers, like polyester and nylon, come from chemicals made from oil. This raises big questions about their effect on the environment. The industry is working to make these processes better and reduce waste.

It’s important to know how these methods affect our health and the planet. The textile world is moving towards more sustainable ways. This includes using fewer chemicals and finding bio-based options.

To learn more about textile production, check out this guide on fiber production methods.

Preparing Fibers for Manufacturing

Getting fibers ready for making textiles is key to quality. First, fibers are cleaned to get rid of dirt and oils. This makes them ready for spinning and weaving. Fibers are then aligned to improve their properties, making the next steps easier. Silk fibers need special care because they are so delicate.

Cleaning and Aligning Fibers

Cleaning fibers is a must to remove dirt and oils. Tools like hand carders help align fibers, making them uniform. This step is crucial for the final product’s quality, ensuring it’s consistent in texture and strength.

- Removes contaminants that could weaken fabric quality.

- Ensures fibers are positioned correctly for spinning.

- Improves the overall aesthetics of the yarn and fabric.

Special Considerations for Silk

Silk production has its own set of techniques. It starts with unwinding silkworm cocoons, needing careful handling. Artisan skill is vital to keep the fibers intact and maintain quality. Key points include:

- Gentle handling to preserve fiber integrity.

- Careful quality control during cocoon processing.

- Attention to detail to enhance the luxurious feel of silk fabrics.

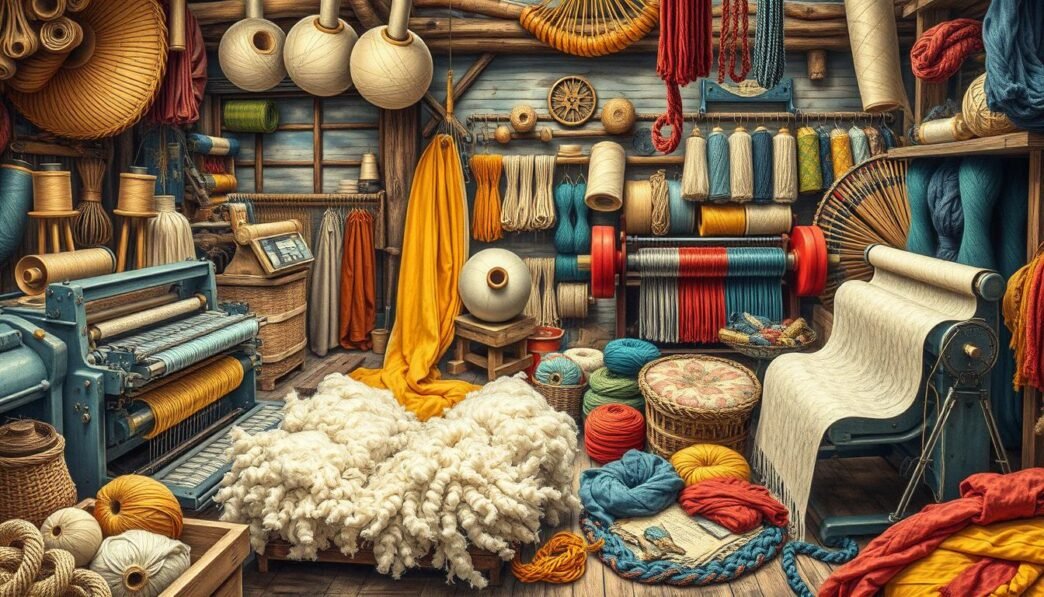

Textile Manufacturing: Spinning Fibers into Yarn

Turning fibers into yarn is key in textile making. It affects the quality and look of the fabric. Different yarn production methods are used to spin fibers, whether they’re natural or synthetic. Knowing the old and new ways of making yarn shows the art and science behind it.

The Traditional Spinning Techniques

Long ago, spinning used drop spindles and spinning wheels. These tools needed a lot of hand skill. People twisted fibers into yarn, sometimes combining threads for more strength.

The spinning wheel, a big step in the Middle Ages, made spinning faster. It helped make yarn from wool and cotton more efficiently.

Modern Innovations in Yarn Production

New modern textile technology has changed yarn making. Natural fibers like cotton are cleaned well before spinning. Today’s machines make yarns that are the same all the way through.

Methods like ring spinning, air-jet spinning, and open-end spinning are part of this change. Each one is used for different yarns, focusing on quality and speed.

Weaving: Crafting the Fabric

The art of weaving turns threads into beautiful fabrics. It uses different methods to create unique textures. Weavers use various loom technologies to make fabrics for specific needs and looks.

The Role of the Loom in Textiles

The loom is key in weaving, helping arrange threads. It ensures threads are woven correctly. From handlooms to modern machines, looms make textiles versatile and efficient.

Different Weaving Techniques

Many weaving techniques make textiles special. Here are some main styles:

- Plain Weave: This simple pattern makes fabrics like percale and muslin.

- Twill Weave: It creates strong fabrics like denim and gabardine with diagonal patterns.

- Satin Weave: Known for its shiny look, it makes fabrics like slipper satin and sateen.

- Jacquard Weave: This method makes detailed designs, seen in brocade and damask.

Each technique has its own features, like warp and filling counts. These affect the fabric’s texture and strength. Innovators like Rajan Vankar, who practices Kutch weaving, blend tradition with modernity.

Dyeing and Printing Techniques

Dyeing and printing are key steps in making textiles. They add color and beauty to fabrics. Many textile dyeing methods help decide how a product looks and feels. Wool is often dyed as loose fibers for better color absorption.

There are many dyes for different uses, like acid and direct dyes. Reactive dyes, introduced in the mid-20th century, are known for their colorfastness. The dyeing process must make sure the color stays, even when washed or exposed to light.

Tests like those from AATCC and ECE check how well colors stay on fabrics. These tests rate lightfastness from 1 to 8. Dyes are often mixed to get bright colors, especially on fabrics made of different fibers.

Modern dyeing machines, often made of stainless steel, can be expensive to run. Early dyes came from nature, but artificial dyes introduced in the mid-19th century offered more colors and stability. Choosing the right dye is important, depending on the fiber type.

Fabric printing techniques have also improved, enabling detailed designs on fabrics. This art has roots in ancient India and Egypt. Today, it requires skilled artists and designers to create beautiful products.

| Dye Type | Suitable Fiber Types | Main Application |

|---|---|---|

| Reactive Dyes | Cotton, Viscose | Lively, durable color |

| Acid Dyes | Wool, Silk, Nylon | Bright shades, high fastness |

| Disperse Dyes | Polyester, Acetate | Excellent for synthetic fibers |

| Vat Dyes | Cotton, Cellulosic Fibers | Deep hues, great lightfastness |

| Sulfur Dyes | Cotton, Cellulose | Cost-effective dyeing |

| Basic Dyes | Acrylics | Bright colors, easy application |

Fabric Finishing Processes

Fabric finishing is key to making textiles better. It changes the fabric’s texture, use, and look. This makes fabrics more appealing to buyers. Different techniques can greatly improve how well and long textiles last.

Key Finishing Treatments

Many treatments are used in the textile world to change fabric properties:

- Singeing: This removes loose fibers for a smoother look.

- Desizing: It removes agents used in weaving for a clean fabric.

- Scouring: A hot wash with alkali and detergent for a deep clean.

- Bleaching: Uses different methods for different fibers; cotton uses alkaline hydrogen peroxide, wool acidic agents.

- Mercerization: Makes cotton fabrics shine and stronger.

- Drying: Uses a stenter machine to stabilize moisture.

- Calendaring: Presses fabric between rollers for a glossy finish.

Each treatment is vital for improving fabric quality. It helps textiles meet various needs in different uses.

Impact of Finishing on Fabric Quality

The finishing stage greatly affects fabric quality. Good finishing can make fabrics stronger, more durable, and comfortable. Treatments like heat setting keep the fabric’s structure intact. Processes like compacting reduce shrinkage during washing.

Special finishes add important qualities, such as:

- Stain resistance

- Water repellency

- Anti-microbial properties

- UV resistance

- Fire retardancy

These improvements are valuable but can raise costs and time. Now, makers are looking for green options to solve sustainability issues with some chemical treatments.

| Treatment | Purpose | Typical Fiber |

|---|---|---|

| Singeing | Removes protruding fibers | Cotton, Wool |

| Mercerization | Enhances strength and luster | Cotton |

| Scouring | Washes and prepares fabric | Cotton, Wool, Synthetic |

| Bleaching | Improves whiteness | Cotton, Wool, Synthetic |

| Calendaring | Imparts high sheen | Cotton, Synthetic |

Environmental Considerations in Textile Manufacturing

The environmental impacts of the textile industry are growing. The global clothing and footwear sector alone generates about 3.9 billion tons of CO2 emissions each year. This is around 8 to 10% of all global CO2 emissions. It shows we need eco-friendly practices to reduce pollution and promote sustainability.

In Europe, the textile industry is a big contributor to climate change. It’s one of the most polluting sectors, after food, construction, and transportation. This highlights the need for new, responsible practices to protect our ecosystems.

Textile production has doubled from 2000 to 2015, reaching about 100 billion items per year. By 2030, it could increase by 63%. With Europeans consuming 15 kilograms of textiles yearly, focusing on sustainability is key for the environment.

Water usage is another big issue. The textile sector uses about 79 billion cubic meters of water each year. For example, making one cotton T-shirt needs around 2,700 liters of water. This is enough for a person to drink for 2.5 years. It shows we need to use less water in textile production.

The industry also relies heavily on synthetic fibers, which increase greenhouse gas emissions. Over 8% of global emissions come from synthetic fibers. Textiles also end up in landfills, with a recycling rate of just 14.7%. Moving towards circular business models can help reduce waste and extend garment life.

| Environmental Impact | Data |

|---|---|

| CO2 Emissions | 3.9 billion tons annually |

| Water Consumption | 79 billion cubic meters (2015) |

| Cotton T-Shirt Water Requirement | 2,700 liters |

| Recycling Rate | 14.7% (2018) |

| Global Impact on Water Pollution | 20% of total |

In conclusion, we need to tackle the environmental impacts of the textile industry. By using innovative and responsible practices, we can make the industry more sustainable. Focusing on eco-friendly methods and encouraging consumers to be responsible will help reduce our ecological footprint.

Global Impact of the Textile Industry

The textile industry has a big impact on the world’s economy. It shows how we consume and produce goods, affecting both local and global markets. In 2019, the U.S. imported $127.7 billion in textiles and apparel. This shows the industry’s big role in the economy.

Textiles are more than just products; they carry cultural values and traditions. New technologies are making manufacturing better, helping the U.S. stay ahead in textile production. Groups like AFFOA and the ARM Institute are working to boost domestic manufacturing and inspire innovation.

Technology has changed the industry, making textiles smarter and more functional. We now have fabrics that can sense things and change color. These advancements bring new creativity and uses to the textile sector.

The textile industry also has environmental impacts. It’s a big source of carbon emissions and water pollution. For example, making a cotton t-shirt uses about 2,700 liters of water. This shows how unsustainable some production methods are.

Globalization brings new ideas and practices in textiles, but it also raises concerns about labor and the environment. Fast fashion has led to more waste and ecological problems. Moving towards a circular economy is key to solving these issues.

| Key Statistics | Data |

|---|---|

| U.S. Textile Imports (2019) | $127.7 billion |

| Employment Decline Since 1990 | Approximately 80% |

| Global Contribution to GDP | About 2% |

| Global Carbon Emissions from Textiles | 10% |

| Water Required for Cotton T-Shirt | 2,700 liters |

Conclusion

The journey from fiber to fabric is a mix of old ways and new ideas. It shows how complex making textiles is. This process makes us appreciate our clothes more and shows the need for better technology.

As the industry grows, it’s key to use new textile tech and focus on green materials. This mix of old and new will lead to a bright and eco-friendly future.

Countries like Italy, Sri Lanka, and Guatemala are big in exporting textiles to the U.S. They show how quality and fair prices can work together. The numbers tell us about the changes in the global textile market.

These stats help companies plan and also make consumers think more about green choices. People are starting to care more about the planet.

The future of making textiles depends on better connections between makers and buyers. This could lead to more custom-made products that make everyone happier. The push for new ideas and green practices will shape the industry’s next steps.