Did you know that almost 90% of manufacturers saw big drops in programming time with CAM software? This amazing tool has gotten better since the late 1940s. It’s now easy to get and affordable for different kinds of businesses, especially small family ones. CAM software makes manufacturing automatic. This improves how CNC machines work, cuts costs, and makes sure products are top-notch.

When businesses start using Computer-Aided Manufacturing, they save a lot of time and money. Today’s CAM software can handle both adding and taking away material, making operations smooth. This lets manufacturers do more work and get better results.

Key Takeaways

- CAM software automates both additive and subtractive manufacturing, improving overall efficiency.

- Accessibility of CAM software has revolutionized operations for small and family-owned businesses.

- Investing in CAM software offers manufacturers significant returns through time and cost savings.

- Modern CAM solutions enhance precision and accuracy in CNC machining operations.

- Integration of CAD/CAM allows for seamless transition from design to finished product.

Introduction to CAM Software and CNC Machining

CAM software boosts the efficiency of CNC machining. It serves as a link between design and production. By using smart workflow strategies, companies can make high-quality products faster.

With the rise of Manufacturing Automation, adding CAM to CNC is key. CAM software automates programming and creates NC files. This cuts manual work, lowers mistakes, and raises efficiency. CAD and CAM software talk through file formats like IGES and STL for smooth operations.

CNC machining is now embracing AI technology. This allows CAM software to bring in smarter manufacturing methods. These enhance productivity and raise production quality. For manufacturers, understanding these links is crucial to improve processes and stay updated with trends.

Defining CAM Software and Its Evolution

The definition of CAM covers technology that makes designs ready for CNC machines, making manufacturing smoother. CAM software’s journey began after World War II, with the first NC machines. This evolution sped up in the 1960s with the appearance of CNC machines, changing how things were made.

At first, only big companies could use CAM tools. They needed lots of resources and know-how. But, as time went on, CAM software evolution made these tools cheaper and easier to use. The late 1970s brought CAD/CAM systems, mixing design with production. This was a big change in making products.

The 1980s and 1990s saw new software like AutoCAD in 1982, and then Pro/ENGINEER and SolidWorks in the 1990s. These programs introduced simulation and better rendering. By the early 2000s, CAM started to include these advanced features too.

Today, many fields like car making, space, electronics, and health care use CAM software. It’s getting better with AI and machine learning to do tasks and improve designs. This shows how important CAM software is now in making things.

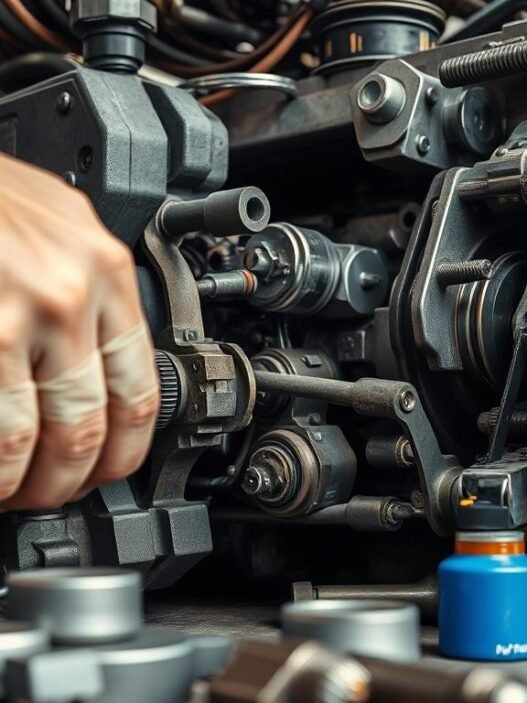

Understanding How CAM Works With CNC Machines

Exploring CAM and CNC machines shows us how modern production thrives. These technologies work together to make high-quality parts fast. This teamwork boosts manufacturing efficiency greatly.

Key Components of CAM Software

The power of CAM systems comes from three main parts. These are:

- CAM Software: It creates the best paths for tools in machine operations.

- CNC Machines: Devices that turn materials into final products using the CAM software paths.

- Programming Language: G-code, the language for machine instructions, controls speed, feeding, and cooling.

These elements enhance CNC use. They help prevent mistakes before making a part. This leads to better products through smart automation.

Automated Manufacturing Processes

CAM software automates making things with additive and subtractive methods. Additive methods like 3D printing build up parts layer by layer. Subtracting, however, removes material to get the end shape. Automation speeds up making things, cuts errors, and can handle complex designs better than by hand.

CAM and CNC working together make manufacturing efficient. Engineers use CAD drawings in CAM software to start operations like drilling or cutting. This partnership simplifies making things from start to finish. It shows why knowing CAM’s role is crucial in today’s manufacturing world.

Selecting the Correct CAM Software for CNC Enhancement

Choosing the right CAM Software is crucial for your CNC operations. It must match your manufacturing processes to boost performance. Look at compatibility, functionality, and features carefully. This ensures the software can meet your needs now and in the future.

Considerations for Compatibility

Compatibility is critical when selecting CAM software for manufacturing. Make sure the software works well with your current CAD systems and CNC machines. It should read and convert data precisely, maintaining your workflow.

This preserves time and improves productivity significantly.

Features to Look for in CAM Software

When picking CAM Software, think about what your CNC operations need. Key features to look for include:

- User-friendly interfaces that are easy to use.

- Scalable CAM Solutions that can grow with your business.

- Robust functionality for the types of machining you do.

- Regular updates to enhance software effectiveness.

- Strong support networks for quick problem-solving.

Don’t overlook the software developer’s reputation. A reputable brand means reliability and continuous support. This is crucial for your success over time.

The Purpose of CAM Software in the CNC Arena

CAM software has become a game-changer in CNC machining. It boosts manufacturing efficiency in big ways. By automating machining aspects, it cuts down on production times and labor costs.

This tech not only makes workflow smoother but also lessens mistakes. This leads to a more trustworthy and effective machining process.

Improving Manufacturing Efficiency

With CAM software, making things becomes more efficient. It does this by speeding up toolpath calculations. Time saved can be up to 80% from design to first cut.

This is key in markets where making things quickly can put you ahead.

Ensuring Precision and Accuracy

In sectors like aerospace and automotive, being precise is critical. CAM software makes sure CNC machining is accurate. It does this by cutting down on manual errors and perfectly copying complex designs.

Customizable tool libraries and post-processors help fine-tune machining. This ensures high-quality production.

To learn more about these advantages, click here for additional insights. This info will expand your understanding of how CAM is changing the CNC industry.

| Aspect | Manual Methods | CAM Software |

|---|---|---|

| Programming Time | 2.3 hours | 13-190 minutes (varies by task) |

| First Cut Timeline | — | 80% reduction |

| Training Duration | Over 6 months | 1 hour (AI-powered automation) |

| Scrap Reduction | Variable | Significantly lower |

Integrating CAD/CAM for Enhanced Production

The merging of CAD and CAM tech significantly changes the manufacturing process. By combining these systems, companies can improve workflow optimization. This increases productivity and cuts down on mistakes. A smooth move from design to making ensures CAD updates show in CAM quickly. This speeds up the time it takes to make things.

Streamlining Workflows through Integration

Combining CAD and CAM makes workflows smoother. This lets teams work better together. The single platform leads to efficient design processes that boost quality. Teams use one model for both designing and making. This cuts mismatches and makes sure the final item matches budget and time plans.

Facilitating Real-Time Collaboration

In today’s quick manufacturing world, real-time collaboration is key. Better team communication in manufacturing lets design, engineering, and making teams join forces easily. Quick access to details and models means fast feedback, sparking innovation. This teaming up doesn’t just raise product quality. It also gives a competitive advantage in a tech-driven market.

Unveiling the Benefits of CAD and CAM Integration

The combination of CAD and CAM brings many advantages. This greatly benefits the manufacturing process. Companies see less waste and better teamwork. They can quickly adjust designs and constantly make products better.

Enhanced Efficiency and Product Quality

One major benefit is improved efficiency. Automating manufacturing processes makes things run smoother. Directly applying design requirements to 3-D models speeds up updates. It also reduces mistakes and costs.

These systems also have tools that make parts and tools better. Tools like collision detection during simulations help improve quality. Keeping data organized helps teams work well together. It lets them quickly handle design changes. Plus, more designers can work on one tool at the same time.

Rapid Prototyping Capabilities

Rapid prototyping is another big plus. Advanced CAD software speeds up design changes. This makes the design process more flexible. It lets companies use feedback sooner and get products out faster.

These integrated systems shorten the time from design to production. This makes everything more efficient. CAD and CAM working together not only cut waste. They also make tool paths better. This shortens cycle times. So, manufacturers can make better parts faster and cheaper. This is a big deal in the competitive world of manufacturing. Learn more about it here.

Challenges and Solutions in CAD/CAM Integration

Combining CAD and CAM tech brings up several issues, especially in manufacturing. A big problem is making different software work together, which can cause mistakes and mismatched data. To overcome these issues, companies must focus on training employees on how to use CAM software. With the right training, employees can handle software problems better, making everything run more smoothly.

Compatibility and Training Issues

Integrating CAD and CAM systems well is key to avoiding problems. When companies use updated software and properly train their staff, processes can get more efficient. However, if they stick with old software or overlook training, it can slow down projects and hurt quality. So, investing in good training helps employees get better at using both CAD and CAM systems. This reduces problems related to training and daily operations.

Hardware Reliability Considerations

For CAD/CAM to work well, the hardware must be reliable. Keeping CNC machines in good shape is crucial. If machines aren’t cared for properly, it can cause expensive delays and affect their reliability and how well they make products. To avoid common issues, manufacturers should maintain their equipment regularly and choose quality hardware. This helps improve both efficiency and quality in making products.