Did you know precision manufacturing is key in aerospace, medical, and automotive fields? It’s part of a multi-billion dollar industry. Roberson Machine Company has more than 20 years of experience in CNC machining. This tech uses automated machining for top-notch accuracy and reliability in creating complex parts.

Today, quality and efficiency are more important than ever in a competitive market. CNC machining is vital, helping industries meet tough standards while cutting down on how long it takes to make things. In today’s precision-focused world, CNC machining is essential, not just a luxury, in modern making of things.

Key Takeaways

- CNC machining utilizes automated processes for enhanced precision and efficiency.

- Roberson Machine Company has over two decades of experience in the field.

- The aerospace and medical industries rely on precision manufacturing for critical components.

- CNC machining can achieve tight tolerances up to +/- 0.0001 of an inch.

- Precision manufacturing is essential for optimizing performance and safety in the automotive sector.

- Technological advancements are transforming manufacturing standards across various industries.

Understanding CNC Machining

CNC machining, also known as Computer Numerical Control machining, marks a big leap in how things are made. It lets machines make parts with high precision, thanks to computer control. This method changes how products are made.

This technique covers turning and milling with many machines like lathes and milling machines. It’s vital in fields like aerospace and medical devices. They can make complex shapes more easily, reducing errors seen in older methods.

Turning CAD designs into CNC code is where CAM software comes in. Tools like Mastercam and Autodesk Fusion 360 make sure designs are properly turned into machine commands. Nowadays, learning CAD software is easier with many online resources for all levels.

To get the best results, setting up the CNC machine right is key. You’ll need to clean the machine, set up tools correctly, calibrate, and load the code. Using top-quality tools helps in getting precise parts and smooth finishes. CNC can do complex 3D cuts in one go, showing the efficiency of automated manufacturing.

The role of CNC machining keeps growing, especially where precision is crucial. It remains a key part of advanced engineering.

Key Advantages of CNC Machining

CNC machining is a top choice in many fields because it offers big benefits. One key advantage is its precision. CNC machines make parts with outstanding accuracy. This means fewer mistakes and better quality products.

Another big plus is consistency. CNC machining’s automation leads to uniform products. This helps keep manufacturing quality high and reliable.

Efficiency is also a major benefit. CNC machines work non-stop, handling complex tasks all day, every day. This increases productivity and cuts down on time needed to finish jobs. It’s great for industries under tight schedules.

CNC machining is praised for its flexibility too. Machines can quickly switch tasks with easy reprogramming. This is crucial for custom orders that change often. CNC machining combines these benefits, showing its true value. For more info on CNC machining benefits, check out how Oracle Precision is using new tech to enhance quality and cut costs.

| Advantage | Description | Impact |

|---|---|---|

| Precision | Ensures products meet exact specifications | Reduces defects, improves product quality |

| Consistency | Uniform production quality through automation | Makes quality assurance easier |

| Efficiency | Continuous operation without breaks | Increases productivity across manufacturing |

| Flexibility | Easily reprogrammed for different tasks | Facilitates quick changes in production |

CNC Machining and Precision Manufacturing

CNC machining is key in precision manufacturing. It maintains tight tolerances which are crucial. Industries like aerospace and medical depend on precision. They need parts made with extreme accuracy. CNC machining provides the necessary tools to meet these high standards.

Importance of Tight Tolerances

Precision manufacturing requires following tight tolerances, which CNC machining does very well. It can achieve tolerances as tight as ±0.001 inches. This needs special equipment and techniques. It’s vital, especially where small errors can cause big problems.

Industries with high stakes, like aerospace and military, use materials such as aluminum and PEEK. They need components made with exceptional precision. This ensures reliability and safety in their operations.

Enhanced Speed and Efficiency

CNC machining boosts efficiency and speed without losing product quality. It can do many operations in one setup. This shortens cycle times and gives a competitive advantage. Manufacturers can make parts quickly while sticking to needed tolerances.

This efficiency helps with rapid prototyping and mass production. It improves delivery times and overall productivity.

| Feature | CNC Machining | Traditional Machining |

|---|---|---|

| Tight Tolerances | ±0.001 inches | ±0.005 to ±0.1 mm |

| Machining Speed | High, with rapid cycle times | Moderate |

| Setup Time | Reduced due to multi-operation capacity | Longer due to single-operation focus |

| Consistency | High with automated processes | Variable |

| Material Versatility | Wide range, including metals and plastics | Limited selection |

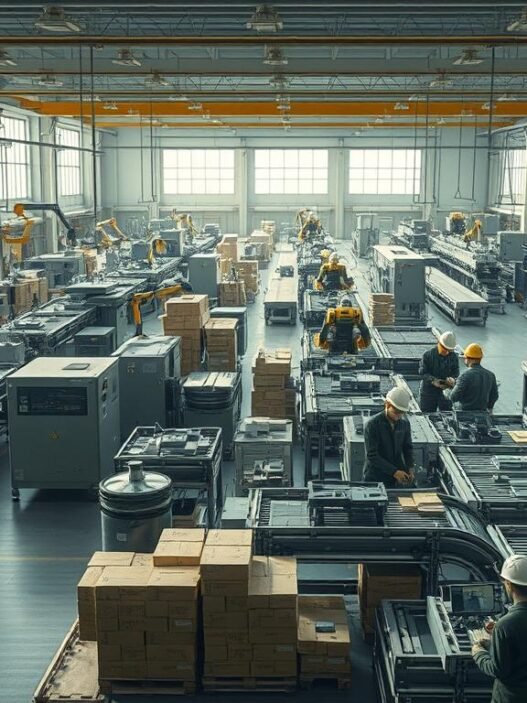

Applications of CNC Machining Across Industries

CNC machining has changed many industries by making parts with incredible accuracy. It is key in aerospace, medical, automotive, and electronics. This shows how flexible and useful it is.

Aerospace Industry

The aerospace industry depends on CNC machining for parts like engine components and landing gear. These parts need to be made very precisely, within tolerances of 4μm, to keep flights safe. CNC machines also make complex parts like turbine blades and avionics, where accuracy is crucial.

Medical Industry

In the medical devices sector, CNC machining makes custom tools, implants, and orthopedic devices. Making parts this way makes surgeries go better and keeps patients safe. Devices such as knee and hip replacements are made accurately with CNC technology.

Automotive Industry

The automotive industry uses CNC machining a lot for parts like engine blocks and gearboxes. Because of how many cars are made, these parts need to be exact. CNC machining makes parts quickly and meets the strict safety standards of cars today.

Electronics and Consumer Goods

In electronics manufacturing, CNC machining is crucial. It makes things like circuit boards and precise parts for gadgets. Big tech companies, like Apple, use CNC for parts like the MacBook Pro’s case. This method helps meet the high demand for gadgets by making small, detailed parts efficiently.

Want to know more about how CNC machining is changing industries? Visit this resource.

Technological Innovations in CNC Machining

The world of CNC technology advancements is changing fast. New innovations make manufacturing better than before. Now, CNC machines have automation and AI software. They help with checking the machines in real-time and fixing them before they break.

Robots are now part of CNC machining too. They make it easy to produce things, doing it fast and with great care. This change meets the growing need for advanced manufacturing in many areas.

New materials science breakthroughs have also changed CNC machining. Machinists can now use special metals designed for the aerospace and car industries. There’s also a push towards using materials that are better for our planet. This includes things like biodegradable plastics and metals that can be recycled.

Being exact is super important in fields like defense, medical tools, and electronics. Advanced engineering is key here. Tools that work with the cloud help turn designs into products fast. CNC machining is keeping up by offering custom products made quickly.

Companies are looking at bringing jobs back to the U.S. to strengthen the economy. This move also encourages new ideas in CNC machining. With the help of smart manufacturing and the Internet of Things, the future of CNC technology looks bright.

Quality Control in CNC Machining Processes

Ensuring top-notch quality control in CNC machining is key. It keeps manufacturing standards high. Companies use strict methods to make sure each part is up to spec. This boosts the integrity of the product and the consumer’s trust.

ISO 9001 & AS9100 Certifications

ISO certifications are crucial for quality management in machining. Getting ISO 9001 means a shop follows key quality controls. For the aerospace and medical fields, AS9100 adds more rules. Having ISO certifications shows a shop’s dedication to quality, making customers happier.

Internal Quality Standards

On top of outside certifications, firms set their own strict quality rules. These include various checks like:

- Regular operator inspections

- In-process probing techniques

- Quality control department audits

Tools such as go/no-go gauges, micrometers, and CMMs are key. The skill of CNC operators greatly affects quality control. Tight internal quality steps help stop production mistakes, boosting CNC machining efficiency.

Quality control finds issues early and cuts down waste and costs. Strong quality management means making top-notch products. It shows a company follows ISO rules well, setting it apart in a fierce market.

| Quality Control Metrics | Importance |

|---|---|

| Defect Rate | Lower defect rates enhance customer satisfaction and reduce costs associated with recalls. |

| On-Time Delivery | Consistent on-time delivery builds trust and reliability in client relationships. |

| Process Audits | Regular audits help identify trends and streamline production processes. |

CNC Machining: A Transformative Force in Manufacturing

CNC machining has profoundly impacted the manufacturing landscape. It has driven significant transformations across various sectors. With this technology, efficiency and precision have improved, meeting the modern production demands.

It uses computer-aided design (CAD) and manufacturing (CAM) to turn ideas into products. This means intricate designs are made accurately, matching the original specs closely. CNC machining has advanced systems like closed-loop machining. These systems check things like position and speed, adjusting them to achieve consistency and reliability in what they make.

CNC machines can work non-stop, boosting productivity and cutting down on downtime. This helps manufacturers meet diverse needs quickly. Whether it’s a small, custom job or a large-scale project, they can handle it. In areas needing precise work, like aerospace or medical fields, this accuracy is crucial for product safety and integrity.

Also, CNC machining lets manufacturers work with many materials and make a variety of designs. It adapts to changing industry needs, sparking ongoing innovation. This makes CNC machining a key part of today’s manufacturing world.

Cost-Effectiveness of CNC Machining Solutions

CNC machining is a top choice for efficient manufacturing today. Many companies worldwide use CNC to save money with precise work and less waste. Companies that understand the value of CNC machining can improve their profits.

Reducing Material Waste

CNC machining is known for its waste reduction. It makes parts that exactly meet needs, so there’s less scrap. This not only cuts down on material costs but also increases profits.

Thanks to its ability to operate all the time, CNC machines produce more while using less. This makes a facility’s operations more cost-effective.

Minimizing Human Error

Automation with CNC machining means error minimization. High-quality results are more consistent because there’s less chance for mistakes. This reduces the need for redoing work and the waste of materials.

With advanced CNC machines, companies spend less on labor. Over time, this leads to big savings.

Conclusion

CNC machining is key in today’s precision manufacturing. It brings many benefits that boost production efficiency. With precise tool control and the ability to make complex parts quickly, CNC technology is crucial in fields like aerospace, automotive, and electronics. These sectors rely on CNC’s high-quality standards and short production times as they grow.

Using CAD-CAM software and G-codes, CNC offers unmatched precision. This method efficiently removes material for complex designs, achieving tolerances as tiny as 0.004 mm. It’s a step ahead of traditional methods. Also, CNC machines can run non-stop. This boosts scalability and keeps companies competitive in the quick-moving market.

The future of machining looks bright with more tech advances expected, like AI and automation. These will make processes even sharper and cut costs. Embracing these advanced manufacturing processes helps companies boost output. They can also adapt swiftly to industry changes. This ensures they stay strong and advance in an ever-changing manufacturing world.