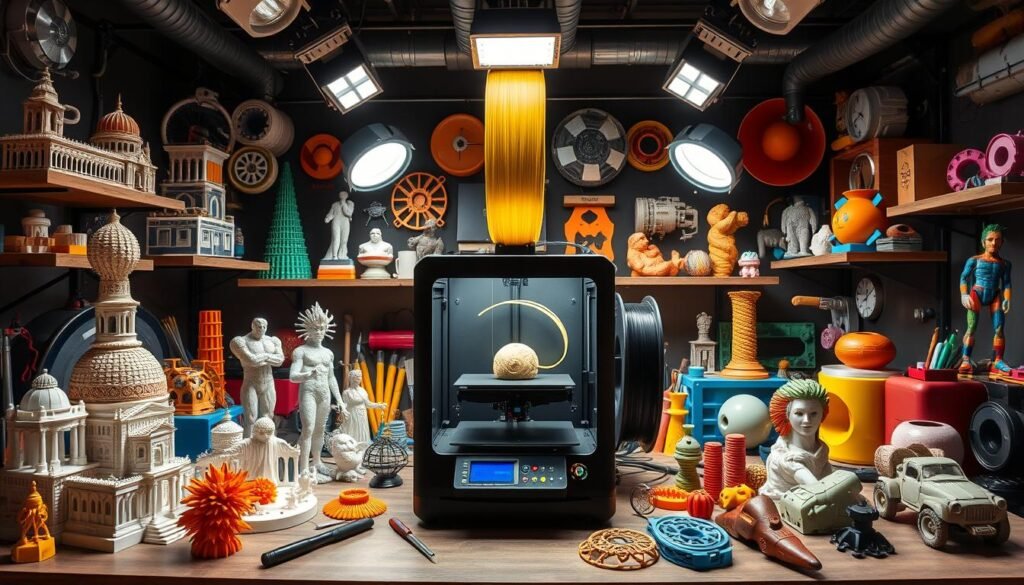

Did you know Charles Hull invented the first 3D printer in 1983? This major breakthrough began the era of modern 3D printing. It has changed many industries like manufacturing, healthcare, education, and art. 3D printing, or Additive Manufacturing, builds objects layer by layer. This is different from traditional ways of making things.

In this guide, we’ll look at 3D printing’s many uses. These include making custom prosthetics in healthcare and quick prototypes in manufacturing. It also lets artists and designers create without limits. Let’s dive into how 3D printing works, the types, materials, and its amazing benefits that are changing our world.

Key Takeaways

- The first 3D printer was invented in 1983, leading to significant advancements in digital fabrication.

- 3D printing is transforming industries like healthcare with customized solutions and efficient production methods.

- Various printing technologies, such as FDM and SLA, cater to different needs and applications.

- Common materials used in 3D printing include PLA, ABS, and Nylon, each suited for specific tasks.

- 3D printing offers unique advantages, including customization, speed, and cost-effectiveness.

What Is 3D Printing?

3D printing, or additive manufacturing, builds objects from digital files by adding layers of material. This is different from traditional manufacturing, which cuts away from a block of material. To truly get what 3D printing is, we need to explore its basics and key ideas.

Definition and Overview

3D printing means using digital designs to make real objects. It can create complex items, like toys or car parts. This technology is growing fast in healthcare and education. For example, doctors use it to make models for surgery or custom prosthetics. 3D printers are now affordable, starting around $300. This makes them accessible to more people and small businesses.

The Basics of Additive Manufacturing

Additive manufacturing includes various techniques, such as agile tooling for fast prototyping. The 3D printing world is rapidly evolving, opening up new possibilities. We might see custom clothes or even printed food in the future. The history of 3D printing goes back to the 1980s with pioneers like Hideo Kodama and Bill Masters. Today, it’s changing manufacturing, offering custom solutions in many fields. For more insight, here’s a detailed overview.

How 3D Printing Works

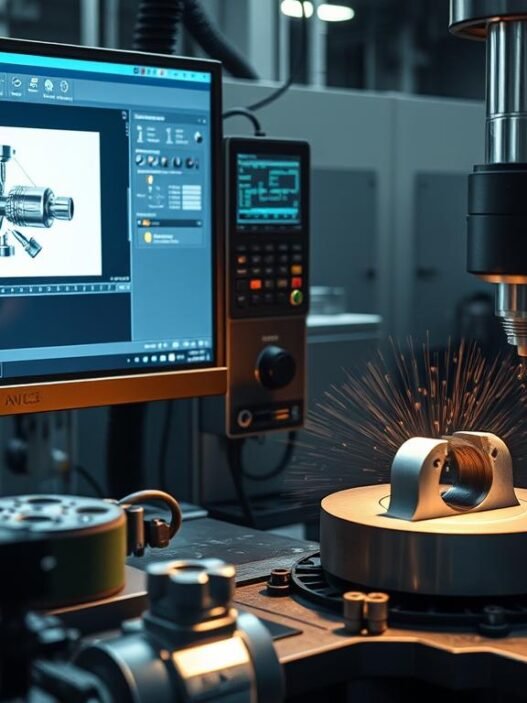

The 3D Printing Process begins with designing. Designers use advanced CAD software to build complex digital models. These models form the basis of the final product. Moving from concept to a digital form is key in making ideas real.

The Design Process

In the first step, creators use different tools to meet various needs. CAD software helps with making detailed designs. This creativity is crucial for the next phases. It’s what makes 3D printing possible.

Converting to STL Files

After designing, the next part is turning these models into STL files. This format is essential for 3D printing. STL files break down shapes into triangles, making them easier for printers to read. This step is vital for accurate printing.

Printing Process Explained

Then, the 3D printing begins. The printer constructs the object layer by layer from the STL files. It might use techniques like FDM or SLS. These methods are fast and versatile, changing how industries work and allow for quick making of prototypes.

The History of 3D Printing

The story of 3D printing is both exciting and important. It started simply but now holds great value in business. The first 3D printer came to life in 1981, thanks to Dr. Hideo Kodama. Since then, the field of rapid prototyping has grown by leaps and bounds.

Through the years, key breakthroughs in 3D printing have led us to the cutting-edge technology we have today. These developments have made their way into modern manufacturing, changing how things are made.

Early Beginnings of the Technology

The early days of 3D printing saw groundbreaking inventions. In 1986, Chuck Hull got the first patent for stereolithography (SLA). This was a big step towards using 3D printing in business.

Soon after, in 1988, Carl Deckard brought selective laser sintering (SLS) into the picture. By 1989, Scott Crump had developed fused deposition modeling (FDM). His work led to the founding of Stratasys, a key player in the 3D printing world.

Evolution and Milestones in 3D Printing

The journey of 3D printing saw major achievements, making the technology more widespread and useful. The RepRap Project started in 2005 aimed at making 3D printers that could replicate themselves. This used FDM technology.

Makerbot came onto the scene in 2009, bringing 3D printing closer to everyday people and beginners. Following this, Ultimaker began in 2011, offering accurate and affordable 3D printing solutions.

The 3D printing industry kept growing, with the market for 3D printed molds and tools hitting $5.2 billion in 2020. It’s expected to reach $21 billion by 2030. The use of 3D printing for final product parts is also set to jump, projected to hit $19 billion by 2030. This growth shows how 3D printing is making manufacturing more flexible, lowering costs, and simplifying supply chains. It’s changing various industries, marking significant achievements as it shapes the future of making things.

Types of 3D Printing Technologies

Various 3D printing technologies have unique benefits for different needs. Knowing these methods helps businesses pick the right one for them. We’ll explore the main types: FDM, SLA, SLS, DLP, and MJF next.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is known for being cost-effective and easy to use. It’s great for making prototypes and simple designs. However, it can’t produce very smooth finishes or very strong parts like other methods.

Stereolithography (SLA)

Stereolithography (SLA) is perfect for making accurate and smooth prototypes. It uses liquid resin to create parts with fine details. SLA is loved for making precise and watertight parts, important in many fields.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is ideal for making strong parts from powder. It’s good for prototyping because it’s cost-effective and works well in busy settings. SLS finds a balance between quality and cost, making it popular across industries.

Digital Light Processing (DLP)

Digital Light Processing (DLP) uses a projector to make parts quickly. It’s similar to SLA but works faster, helping speed up production. DLP’s ability to work with different materials makes it fit for various uses.

Multi-Jet Fusion (MJF)

Multi-Jet Fusion (MJF) cuts down production time and costs compared to SLS. MJF fuses layers effectively, making the printing process faster. With its fast turnaround and flexibility, MJF is a strong choice for today’s manufacturers.

| Technology | Advantages | Limitations | Best Used For |

|---|---|---|---|

| FDM | Cost-effective, user-friendly | Rough surface finish, lower strength | Basic prototyping, simple parts |

| SLA | High-accuracy, watertight parts | Longer build times | Detailed prototypes |

| SLS | Strong functional parts, cost-effective | Requires post-processing | Functional prototyping |

| DLP | Fast build times | Material limitations | Rapid prototyping |

| MJF | Accelerated production, versatile | Complex setup | Low-volume production |

Materials Used in 3D Printing

3D Printing Materials offer a broad range of choices meant to suit different projects. Understanding the common materials is key to a successful and efficient print job. When picking a material, think about what each type offers and how it can help your project.

Common Materials for 3D Printing

Here’s a look at some popular 3D printing materials:

- ABS: ABS is tough. It’s used in both filament and powder form for making strong parts.

- PLA: PLA is biodegradable and made from plants. It’s eco-friendly but not very durable outside.

- PETG: PETG is clear and strong, often chosen for engineering.

- Polyamide (Nylon): Nylon is known for its resistance and toughness. It’s widely used in industry and cars.

- SLA Resins: Formlabs has many resins. They offer high detail and options like quick prototyping with Draft Resin.

- High-performance polymers: Materials like PEEK and ULTEM are strong and light. They’re perfect for aerospace.

Advantages of Different Material Types

Different 3D printing materials have their own benefits for various uses:

| Material | Advantages |

|---|---|

| ABS | Durable, can take a hit, and works well for lots of projects. |

| PLA | It’s green and breaks down naturally, great for prototypes and learning. |

| PETG | It looks clear and holds strong, with a nice balance for engineering. |

| Nylon | Tough and flexible, perfect for use in tough spots. |

| SLA Resins | They show fine details well and have a smooth finish, ideal for detailed work. |

| High-performance polymers | They have top-notch mechanical traits and stand up to heat, fitting for critical uses. |

Applications of 3D Printing

3D printing is changing many industries in amazing ways. It’s being used in healthcare, manufacturing, education, art, and aerospace. Let’s look at how this technology is transforming these sectors.

Healthcare Innovations

3D printing brings big changes to healthcare. Aprecia Pharmaceuticals introduced Spritam®, the first FDA-approved 3D printed drug. This opens doors for making medications locally on demand. 3D printing also allows for custom medical devices.

These include prosthetics and implants tailored for patients. Creating accurate models for surgery improves how doctors plan operations. This helps patients get better faster.

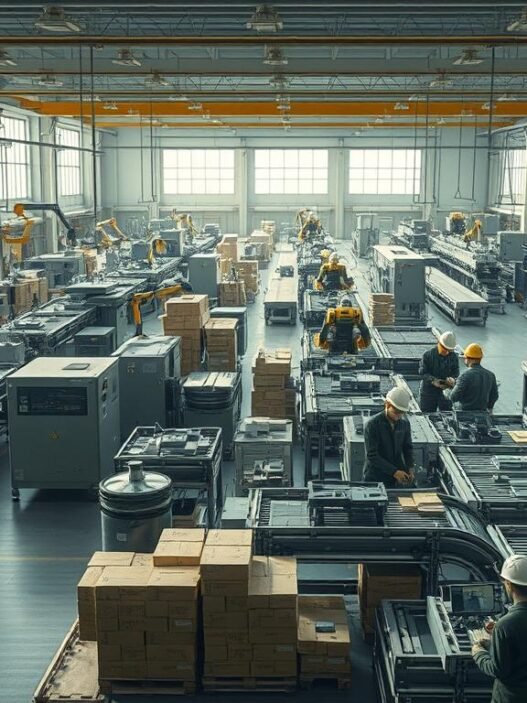

Impact on Manufacturing

In manufacturing, 3D printing has revolutionized how things are made. Ford and Porsche use it to quickly make prototypes and parts. This cuts down on time and costs.

Xometry helps many clients by offering 3D printing services. This makes the production process smoother and ensures high-quality outcomes.

Education and Learning

3D printing makes learning more hands-on and creative in schools. It’s great for subjects like electrical engineering and biomedicine. Students can experiment and build things themselves.

Schools use 3D printers to teach about design and engineering. This encourages teamwork and creativity among students.

Art and Creative Design

Artists are embracing 3D printing for its creative possibilities. It lets them create complex pieces that are hard to make in other ways. This technology opens up new ways to express themselves and customize their work.

The level of detail and customization possible is a game-changer for creatives.

Aerospace and Automotive Uses

The aerospace and automotive fields are leveraging 3D printing too. It allows for making advanced parts like airframes more quickly and lightly. This saves money and boosts efficiency.

Thousands of 3D-printed parts in aircraft show the aviation industry’s embrace of this tech. It sets new benchmarks for innovation.

| Industry | Applications | Examples |

|---|---|---|

| Healthcare | Customized prosthetics, surgical models, drug delivery devices | Spritam®, dental implants |

| Manufacturing | Rapid prototyping, product development | Xometry services, Ford’s parts manufacturing |

| Education | Hands-on learning, prototyping | University projects, engineering courses |

| Art | Sculptures, personalized designs | 3D printed art installations |

| Aerospace | Aerodynamic components, lightweight parts | 3D-printed aircraft parts |

Advantages of 3D Printing

The rise of 3D printing technology has offered many perks across different fields. Industries like fashion and aerospace are now better off because of it. The impact of 3D printing is huge and changes how things are made.

Customization and Personalization

Customization is a big win with 3D printing. It lets designers craft detailed shapes, inside spaces, and complex forms hard to make before. This lets people and companies create special items just the way they need them.

Speed and Efficiency

3D printing makes making things much faster. Products can be ready in a few hours, beating older methods. This speed boosts how quickly businesses can get new products out to people.

Cost-Effectiveness in Production

Setting up for 3D printing takes a good bit of money at first. But, the savings over time are too good to ignore. It cuts down on material and labor costs. This leads to big savings for companies.

Material Efficiency Benefits

Using fewer materials is another plus of 3D printing. Building items layer by layer cuts down on waste. Choosing materials like PLA helps the planet by being more green. This makes making things less harmful to the environment.

| Advantage | Description | Impact |

|---|---|---|

| Customization | Ability to create tailored designs suited for specific applications. | Increases customer satisfaction and brand loyalty. |

| Speed | Rapid production capabilities reduce time to market. | Enhances competitiveness and decreases product lead time. |

| Cost-Effectiveness | Long-term savings with reduced material and labor costs. | Increases profit margins for businesses. |

| Material Efficiency | Minimizes material wastage and supports sustainable manufacturing. | Promotes eco-friendly practices and resource conservation. |

Challenges in 3D Printing

The path to advancing 3D printing is filled with significant hurdles. Overcoming these challenges is vital for its success across industries. It’s important to understand issues like accuracy, material limits, and the need for post-processing.

Accuracy and Precision Issues

For 3D printing to work well, it must be accurate. However, many face accuracy issues, such as size and shape errors. A study shows 52% struggle with making surfaces smooth. These problems make it hard for 3D printing to fit into industries that need high precision. Even though some technologies can create very detailed parts, there’s still much work needed to ensure things are made correctly.

Material Limitations

Choosing the right materials is a big challenge in 3D printing, especially for large-scale production. About 54% of brands say the cost and access to materials are major barriers. Most use plastic, but there’s growing interest in using metal too. To use more metals, we need to find ways to make them affordable and approved for use.

Post-Processing Needs

Finishing 3D printed items is crucial but also costly. It accounts for nearly 27% of the total cost of making prototypes. This stage is needed to smooth out surfaces and remove extra supports. Since 53% mention the long time needed for finishing, finding quicker ways to do this is important for efficiency.

| Challenge Type | Statistics | Industry Impact |

|---|---|---|

| Accuracy Issues | 52% struggle with surface finish consistency | Inhibits use in precision-driven sectors |

| Material Limitations | 54% cite material cost/availability as barriers | Restricts mass production applications |

| Post-Processing | 27% of total production costs attributed to post-processing | Lengthens production timeline and costs |

Future Potential of 3D Printing

The future looks bright for 3D printing. It is full of Technological Advancements that grow fast. These changes help many industries like healthcare and aerospace grow big.

Technological Advancements on the Horizon

3D printing will soon become more automated. This includes real-time quality checks and workflows that don’t need manual help. Such upgrades make making things more efficient and are part of the new Industry 4.0.

New materials are also being developed. These include metal alloys and advanced polymers. For instance, in aerospace, light structures improve parts like engines and satellites.

Potential Industry Growth Areas

Many industries will hugely benefit from 3D printing. Some growth areas are:

- Construction: 3D-printed houses will cost less than traditional ones.

- Healthcare: Bioprinting will help make tissues that help patient cells grow.

- Aerospace: New ways to make engine parts will change supply chains.

- Automotive: Spare parts will cost less and take less time to make.

- Education: Schools will have easier access to 3D printing, supporting new ways to learn.

| Industry | Growth Potential | Technological Innovations |

|---|---|---|

| Construction | Cost-effective housing solutions | Faster printing times, reduced labor costs |

| Healthcare | Development of organ structures | Bioprinting, tissue engineering |

| Aerospace | Enhanced component performance | Lightweight materials, complex geometries |

| Automotive | Efficient spare parts production | Additive manufacturing processes |

| Education | Innovative teaching tools | Increased accessibility for institutions |

As 3D printing gets better, it will change many sectors. It will lead to a new era where digital making is key. The future of 3D printing is truly exciting to watch.

Conclusion

Over the years, 3D printing has grown from a niche technology to a crucial instrument in many fields. It plays a big role in healthcare, manufacturing, and education today. In healthcare, it’s used for making things like prosthetics and surgical tools. During the COVID-19 crisis, it even helped by making safety gear.

The leap from only three 3D printing facilities in 2010 to 113 in 2019 shows how much more we rely on this technology now. The FDA has approved many medical products made this way. This shows how 3D printing is improving care for patients and making things more efficient.

Groups like e-NABLE show us how 3D printing is helping people all over the world by making things they need. Looking ahead, we see big chances for growth in 3D printing. It offers fast design making, customizing things without extra cost, and helps the environment too.

Yet, there are hurdles like ensuring safety, figuring out payments, and speeding up production. Despite these, the benefits show why we need to keep innovating. To learn more about 3D printing, visit this comprehensive guide that covers its different aspects.