Ever wondered how plastic products are made so precisely and consistently? It’s thanks to plastic injection molding machines. These machines are key in making everything from phone cases to car parts.

But what makes these machines so special? How can they help you create your next big product? This guide will show you how these machines work. We’ll explore their history, types, and how they make plastic parts.

Key Takeaways

- Plastic injection molding machines can range in size from 1 ton to over 1000 tons, producing parts from a few grams to several kilograms.

- The cost of these machines can vary widely, from a few thousand dollars for small tabletop models to hundreds of thousands for larger, more complex units.

- Rex Plastics, a leading manufacturer, operates a floor full of injection molding machines with diverse capabilities.

- The global plastic injection molding market is estimated to be worth around $43 million in 2022.

- Mold design and material selection are critical factors in ensuring high-quality, cost-effective plastic parts.

Ready to learn about the plastic products in our lives? Let’s explore the world of plastic injection molding machines. We’ll look at the latest techniques that are changing how we make the things we need.

What is Plastic Injection Molding?

Plastic injection molding turns raw plastic into many identical parts. It heats the plastic until it melts, then pushes it into a mold. There, it cools and hardens into the desired shape. This method is known for being efficient, consistent, and cost-effective, making it great for making lots of parts.

Overview of the Process

The plastic injection molding process has several important steps:

- Polymer pellets or granules are loaded into a hopper attached to the machine.

- The material is then heated and melted in the barrel, creating a molten plastic.

- The molten plastic is then injected under high pressure into a closed mold cavity.

- The plastic solidifies as it cools within the mold, taking the desired shape.

- Finally, the mold opens, and the finished part is ejected, ready for further processing or assembly.

History and Evolution

The idea of plastic injection molding started in the 19th century with the first molding machine patent. But, it was only for simple items like combs and buttons back then. This was because the equipment was basic and there were few thermoplastics available.

In the 1930s, new thermoplastics like polyolefins, polystyrene, and PVC came along. This opened up the injection molding industry. The invention of the extrusion screw injection machine by James Hendry also played a big role. It led to the advanced machines we use today.

“Plastic injection molding has become an integral part of modern manufacturing, enabling the efficient production of a vast array of plastic products we use every day.”

Types of Injection Molding Processes

The world of plastic injection molding is full of different techniques and processes. Each one is designed to meet the unique needs of various industries. From gas-assisted injection molding to thin-wall injection molding, there’s a wide range of options for manufacturers.

Gas-assisted injection molding is a popular choice. It uses materials like Acrylonitrile butadiene styrene, Polycarbonate, and Nylon. This method creates hollow, lightweight parts.

Thin-wall injection molding is all about making parts very thin. It uses materials like Nylon, Polypropylene, and Polyester. This technique is great for making intricate, ultra-thin components.

Liquid silicone injection molding is perfect for parts that need to be strong and durable. It uses materials like standard silicone to medical-grade and optical-quality formulations. This method is ideal for creating parts that need to be flexible yet strong.

Structural foam injection molding is great for making parts that are both strong and light. It uses Polyurethane, Polycarbonate, and other plastics. This technique helps achieve a unique balance of strength and weight reduction.

These are just a few examples of the many injection molding process types available. Each one has its own benefits. Choosing the right process is crucial in the design and manufacturing journey.

The Injection Molding Machine: A Closer Look

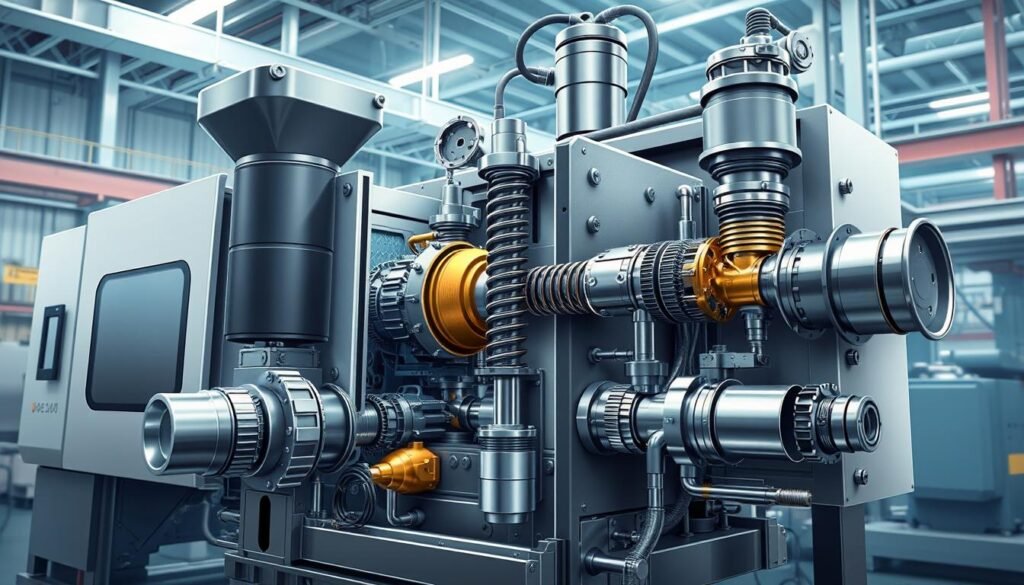

The heart of the plastic injection molding process is the machinery that turns raw plastic into many products. At its core are two main parts: the clamping unit and the injection unit.

Clamping Unit

The clamping unit holds the mold firmly in place during the process. It ensures the product’s stability and precision. It also opens and closes the mold, making it easy to remove the finished part.

Injection Unit

The injection unit is key to the machine, melting plastic and filling the mold. It has a hydraulic cylinder, a hopper, and a rotating screw. Plastic pellets are melted and then injected into the mold at the right speed and pressure.

The clamping and injection units work together to make high-quality plastic parts. Their precision is crucial for the injection molding process.

“Injection molding machines are the foundation of modern plastic manufacturing, transforming raw materials into diverse and essential products that shape our everyday lives.”

Plastic injection molding machines

Plastic injection molding machines vary in size and capability to fit different production needs. Their size is mainly based on their clamping force, ranging from 1 ton to over 1000 tons. Small models can handle parts weighing a few grams, while large machines can produce parts weighing several kilograms.

The cost of these machines also varies a lot. The smallest ones cost a few thousand dollars, while the biggest and most advanced ones can cost hundreds of thousands of dollars. The machine’s technology, features, and production capacity all affect the price.

| Type of Injection Molding Machine | Characteristics | Cost Range |

|---|---|---|

| Horizontal Injection Molding Machine | Most commonly used type with broad applications | $10,000 – $500,000 |

| All-Electric Injection Molding Machine | Higher price than hydraulic models, but more energy-efficient | $50,000 – $750,000 |

| Hybrid (Servo-Hydraulic) Injection Molding Machine | Combines the benefits of hydraulic and electric systems | $75,000 – $1,000,000 |

The market offers many types of injection molding machines. Horizontal machines are the most used, suitable for many applications. All-electric machines are more expensive but more energy-efficient and precise. Hybrid machines try to mix the good points of both, offering a balance of performance and cost.

Manufacturers can find the right machine for their needs and budget. Knowing the options helps businesses make smart choices. This ensures they invest in the best equipment for their plastic injection molding needs.

Mold Design and Material Selection

Injection molding needs the right thermoplastic materials and mold design for quality parts. Manufacturers pick materials based on the product’s needs. They look at things like strength, chemical resistance, and cost.

Thermoplastic Materials

There are over 85,000 thermoplastic options for injection molding. These materials fall into about 45 families, each with its own traits. Most focus is on thermoplastics like ABS, nylons, polycarbonate, and polypropylene.

Each material has its own set of properties. For example, ABS is strong against impact and has a medium price. Nylon is very strong and flexible but costs more. Polycarbonate is great for impact and temperature, making it popular in many fields.

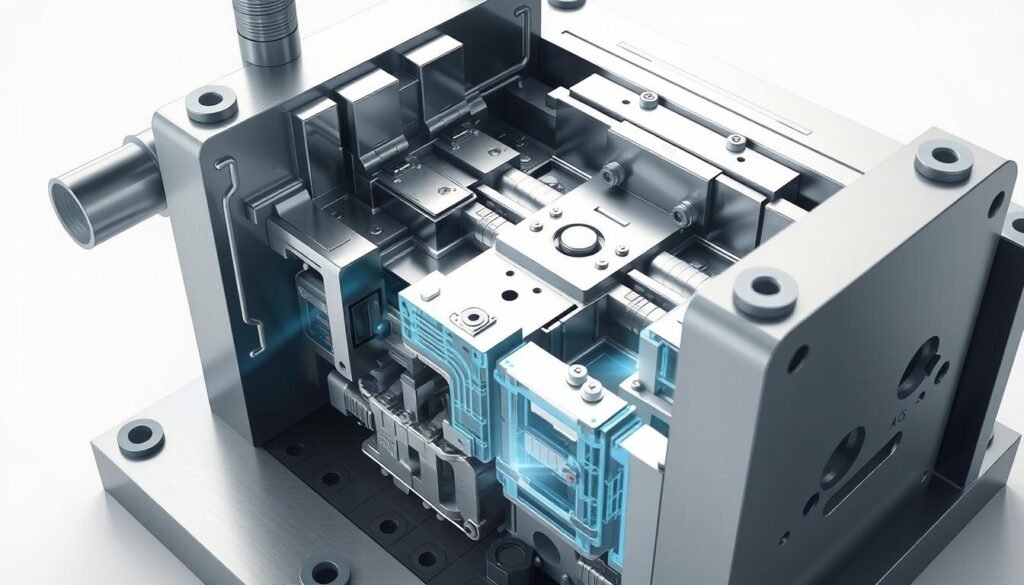

Mold Design Considerations

The mold design is key in injection molding. It shapes the final product. Designers use CAD and 3D printing to test and improve designs before making the final mold tools.

Good mold design and material choice are vital for injection molding success. By knowing material properties and using advanced design, makers can create quality parts at a good price. This meets market demands.

From Prototyping to Production

The injection molding process starts with making prototype molds using CAD software and 3D printing technology. This method lets manufacturers design and test molds digitally first. It saves time and money by avoiding the costly final mold creation.

Using digital design and fabrication, manufacturers can check if the mold fits the product needs. This reduces the chance of mistakes and delays in production.

CAD and 3D Printing for Prototyping

Prototype injection molding is a smart way to learn from mistakes early. It helps speed up projects and boosts creativity. 3D printing is the fastest and cheapest way to get physical prototypes at the start.

Prototype molds are single cavity and take 1-2 weeks to make. Production molds, however, take 8-16 weeks. This makes prototype injection molding great for testing designs and product functions before full production.

| Metric | Prototype Injection Molding | Production Injection Molding |

|---|---|---|

| Tooling Lead Time | 1-2 weeks | 8-16 weeks |

| Cavities | Single cavity | Multi-cavity (2, 4, 8, 16, etc.) |

| Tooling Cost | $6,000 – $15,000 | Varies by complexity |

| Cycle Time | Longer (no heating/cooling) | 45-60 seconds |

By using CAD for injection mold design and 3D printing for injection mold fabrication, manufacturers can make the prototyping process faster and cheaper. This speeds up the journey from idea to production-ready parts.

Precision and Control in Injection Molding

Precision and control are key in the injection molding process. The injection molding pressure control is adjusted carefully. This ensures the mold cavities are filled perfectly without any plastic spill.

The injection and clamp pressures are fine-tuned. This balance is crucial for the part to form correctly.

Pressure Control

The injection molding process parameters are closely watched. This keeps the pressure steady throughout the molding cycle. It leads to high-quality components with injection molding machine precision.

Skilled operators and advanced software help optimize pressure control. They adjust it for each unique product.

Cooling and Solidification

The cooling time is monitored closely. This ensures the plastic solidifies and takes its final shape without defects. After injection, the mold holds the plastic for a specific injection molding cooling process time.

This time varies based on the plastic type and component complexity. Once solidified, the component is ejected from the mold. The cooling and solidification stages are critical for quality and consistency.

For the best results in precision injection molding, understanding the process is key. Skilled operators and advanced machinery are essential. They help manage pressure, cooling, and solidification. This ensures high-quality products that meet modern industry standards.

“Precision and control are the foundation of successful injection molding. By meticulously managing every stage of the process, we can deliver components that meet the most demanding specifications.”

Quality Assurance and Post-Processing

The injection molding process needs careful quality checks to meet standards. Skilled workers watch over each step, from when parts come out to the final touches. These steps include cooling times and tasks like polishing and removing extra plastic.

Quality control is key in injection molding. Workers keep an eye on things like how parts fit together and how they cool. They use advanced methods to make sure every part is perfect.

After parts pass quality tests, they’re checked, packed, and ready to go. Injection molded part inspection is important to make sure parts are just right for customers.

| Quality Control Stage | Key Considerations |

|---|---|

| Design Review | Involve both internal and external designers or engineers to ensure accuracy before production. |

| Mold and Pre-Production Inspection | Verify mold design, material selection, and prototype testing to identify potential issues. |

| In-Process Quality Control | Monitor critical parameters such as temperature, pressure, and cycle time during production. |

| Final Inspection | Thoroughly inspect finished parts for dimensional accuracy, surface quality, and compliance with specifications. |

By focusing on injection molding quality control, makers can create top-notch plastic parts. This focus on quality is vital for the success and dependability of these products.

Conclusion

Plastic injection molding is a complex process that combines many skills. It uses machine design, mold engineering, and the right materials. It also needs precise control to make high-quality plastic parts efficiently.

This method is key in many industries. It helps make durable and innovative plastic products. By understanding this process, manufacturers can improve their work and meet industry needs.

Injection molding offers many benefits. It’s precise, fast, and cost-effective. It also reduces waste and labor needs. Plus, it allows for customization and a high-quality finish.

This makes it essential in fields like cars, electronics, and medical devices. As technology advances, injection molding will get even better. We can expect more automation, better materials, and improved control.

This guide has shown how powerful injection molding is. It gives readers the tools to use it fully and stay ahead in the industry. By using injection molding, manufacturers can create new products and meet the demand for quality and cost-effective plastics.