Did you know precision engineering is all about making products with super tight tolerances? It’s key in fields like aerospace, medical devices, and microelectronics. This shows how vital it is for today’s tech progress1. It’s where art meets science, combining top-notch quality with new designs to make high-performance items. As tech keeps growing, the need for precision engineering’s skill in design is bigger than ever.

We’ll dive into why precision engineering matters, its big impact on many areas, and the latest innovations. Precision engineers focus on quality, with a keen eye for detail and advanced skills. They’re crucial in today’s complex engineering world1.

Key Takeaways

- Precision engineering maintains extremely tight tolerances and precise specifications.

- Industries such as aerospace, medical technology, and microelectronics heavily rely on precision engineering.

- Precision engineers play a significant role in enhancing product quality through innovative designs.

- Advancements in precision engineering incorporate nanotechnology, 3D printing, and robotics.

- Attention to detail and problem-solving capabilities are core attributes of precision engineers.

Introduction to Precision Engineering

Precision engineering is a field that designs parts with very tight tolerances. It’s crucial in many industries because small mistakes can cause big problems. The Definition of Precision Engineering is about making machines and tools that work with incredible accuracy. This is key for fields like aerospace and medical devices2.

This field focuses on Manufacturing Accuracy. It makes sure each part fits perfectly in the bigger system. It looks at how well things work, not just how strong they are. Unlike traditional engineering, precision engineering cares more about how things move and bend2.

Defining Precision Engineering

Precision engineering includes areas like precision machine design and optomechanical engineering. It’s a wide field. It makes Engineering Design better in many areas, leading to more productivity and safety. Its methods help industries work better, faster, and stronger3.

These techniques also make products last longer by reducing wear. They make sure products are made the same way every time. This means fewer mistakes and more consistent quality4. By using precision machining, industries can meet the high demands for accurate products4

The Importance of Precision Engineering in Modern Industries

Precision engineering is key in Modern Industries. It helps reach high Quality Enhancement and Efficiency standards. It’s vital in fields like aerospace, healthcare, and microelectronics.

It makes manufacturing precise, ensuring reliability and safety. It also cuts down waste and costs. The ability to make tiny parts shows how crucial precision engineering is in these fields5.

Enhancing Quality and Efficiency

Modern tools like CNC machines have changed production. They allow for parts to be made with great accuracy. CNC machines can make parts without any variation, which is great for big orders6.

They also make production smoother by cutting out downtime. This boosts Efficiency in making things6.

Precision engineering also improves Quality Enhancement by reducing defects. Even a small error can upset customers. This shows how important it is to make things right5.

Parts made with precision last longer because they wear out less. This shows how precision balances performance with durability5. New methods like spark erosion make work safer by reducing risks from dangerous tools6.

Precision Engineering Applications Across Various Sectors

Precision engineering is key in many industries. It helps companies meet high quality and efficiency standards. It’s used in Aerospace, Medical Devices, and Microelectronics. Let’s look at how it impacts these sectors.

Key Sectors Utilizing Precision Engineering

In Aerospace, precision parts are crucial for safety and performance. They are used in aircraft structures, landing gear, and more. This ensures safety in tough conditions7.

In the automotive world, precision engineering is vital. It helps in making engines, transmissions, and brakes better. This leads to safer and more efficient cars7. CNC machining is a big help here, offering better precision and faster production8.

In Medical Devices, precision engineering is about making life-saving tools. It’s used in surgical instruments and implants. This work is key for patient safety and treatment success7.

Additive manufacturing, like 3D printing, is changing Medical Devices. It allows for quick prototyping and custom designs. This is a game-changer for medical and aerospace tech9.

Smart materials and sensors are being added to devices. This makes them work better and safer. It’s a big step forward in patient care9.

The Microelectronics field needs precision engineering for top performance. Advances have made complex components possible. This shows how crucial precision engineering is for innovation8.

Tools like CMM and optical scanners check the quality of these parts. This ensures they work well and reliably7.

Precision Engineering: Driving Innovation in Aerospace

The aerospace sector shows how important Precision Engineering is for new technologies. High-precision tools like CNC machining centers and laser cutting systems are key. They help make parts that are safe and of high quality.

Advancements in Aerospace Technologies

The global Precision Engineering Machines market is growing fast. It’s expected to go from USD 12.50 billion in 2022 to USD 23.24 billion by 2032, at a 6.4 percent CAGR10. This growth shows how much aerospace relies on this technology. Precision engineering makes important aircraft parts, like turbine blades and landing gear, with high accuracy11.

These parts must meet strict standards to avoid failures and keep flights safe. Using lightweight materials, thanks to precision engineering, is key for new aircraft types like electric and hybrid-electric ones12.

Also, precision engineering makes the aerospace industry more productive and sustainable. It reduces waste and makes production more efficient. This leads to better quality control and the creation of complex, custom aerospace products12.

| Application | Description | Benefits |

|---|---|---|

| Turbine Blades | Manufactured with precision for optimal performance. | Enhances engine efficiency and safety. |

| Landing Gear | Fabricated to meet strict tolerance standards. | Improves reliability and reduces maintenance costs. |

| Heat Exchangers | Built using advanced materials for better thermal management. | Increases operational efficiency and lifespan. |

| UAV Components | Engineered for precision in various applications. | Supports advancements in drone technology and capabilities. |

Precision Engineering is changing the aerospace industry for the better. It focuses on safety, efficiency, and less environmental harm. The ongoing development of these technologies shows how crucial precision is for both manufacturing and advancing aerospace technologies101112.

Advancements in Precision Engineering Technologies

Precision engineering has made huge strides thanks to new technologies. The Industrial Revolution started this journey, moving from old crafts to new tech. In the 1950s, CNC machines came along, making things more precise by automating them13.

Now, we have 3D printing, AI, and digital twins changing the game. These tools are making things better in fields like aerospace and medicine1413.

Future Technologies Influencing Precision Engineering

The future looks bright with IoT, advanced robots, and quantum computing on the horizon14. These will make things better and greener by using new materials and designs13.

With the digital age, we can watch and control things in real time. Data and AI help make smarter choices in this field1315. But, people are still key. Their skills and creativity keep pushing the limits of what’s possible14.

The Role of CAD in Precision Engineering

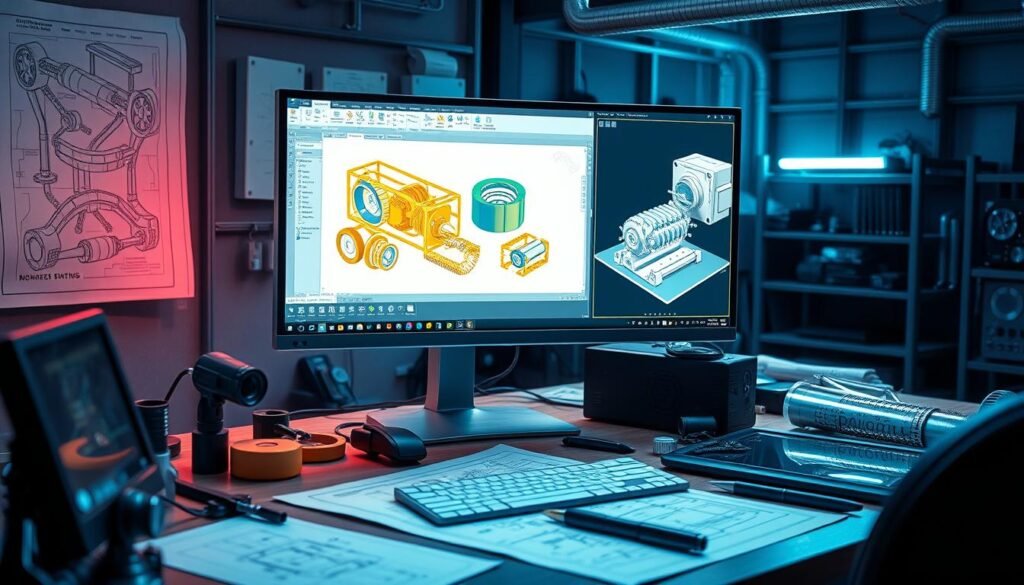

Computer-Aided Design (CAD) is key in precision engineering. It changes how engineers design things. CAD lets them make detailed models of parts and systems, which is crucial for accuracy.

Being able to see and check designs before making them saves time and money. This is especially true in areas like aerospace, automotive, and medical devices. These fields use CAD and CAM technologies a lot.

Importance of CAD Technology

CAD technology is very important in design engineering. It makes it easy to create prototypes quickly. Engineers use 3D CAD models in many fields, like aerospace and automotive.

These models are more accurate than drawings. They help engineers see how parts work together and find problems early. This helps avoid mistakes and keeps things safe by fixing small errors1617.

CAD also lets engineers check how materials behave under stress. This is very important for safety and performance in certain industries. Using CAD with new tech like AI and machine learning makes design better and faster17.

CAD is very important in precision engineering. It helps engineers make changes quickly, which saves money and time. Every industry, from aerospace to medical devices, benefits from CAD. It helps them make sure their projects are accurate and reliable1617.

| Industry | Benefits of CAD |

|---|---|

| Aerospace | Ensures safety and efficiency through accurate designs |

| Automotive | Facilitates design of complex assemblies for functionality |

| Healthcare | Supports the creation of precise medical devices |

| Construction | Improves project planning with accurate 3D models |

Precision Engineering in Healthcare: Lifesaving Innovations

Precision engineering has changed healthcare by making medical innovations better. These new tools help doctors care for patients more effectively. They make sure medical devices work well and are very helpful.

Transformative Medical Devices

New medical devices, like robotic surgeries and AI diagnostics, have changed the game. They help doctors treat patients better and faster. This means patients can get back to their lives sooner18.

Also, things like MRI and CT scans are clearer now, thanks to precision engineering. This is key for doctors to make accurate diagnoses19.

Cochlear implants are another example of how precision design helps people. They improve hearing for those with hearing loss19. Precision tools are also crucial for catching diseases early, like diabetes and cancer19.

Drug delivery systems have also been improved. Now, drugs can be given in ways that are less invasive19.

Robotic surgeries are making recovery times shorter. Patients can get back to their lives faster19. Sensors that monitor vital signs are another example. They keep track of patient health continuously19.

This shows how precision engineering in healthcare leads to big changes. These changes have a huge impact on how we care for patients.

Challenges Faced in Precision Engineering Projects

Precision engineering is key in many industries, but it comes with big challenges. Companies face big challenges in precision engineering as they try to keep up with new tech. Design complexity often makes it hard to make things exactly right.

Many projects end up costing more because of detailed designs and tight tolerances20.

Overcoming Precision Engineering Obstacles

Choosing the right material is also a big problem. It’s crucial for how well a product works, but many struggle with this choice20. Bad communication can also cause delays and mistakes, showing how important clear talk is20.

Meeting tight specs is hard, and unclear definitions can hurt product quality20. Budget issues can make things worse, especially when comparing custom and small orders. Companies must find ways to save money without sacrificing quality20.

In the oil and gas world, the tough conditions make things even harder. Machines need to be reliable and safe in harsh environments. Precision engineering helps by making equipment better and safer21.

In short, precision engineering needs careful handling of many things. This includes design, material choice, specs, and communication. Overcoming these hurdles improves product quality and keeps companies competitive21.

The Future of Precision Engineering: Trends and Predictions

The world of precision engineering is changing fast. New technologies and market needs are driving these changes. We’re moving towards more innovation, sustainability, and efficiency. This shift is led by Industry Trends that focus on making customers happy and following rules.

Anticipating Tomorrow’s Engineering Landscape

The global precision engineering market is expected to grow from $59.1 billion in 2020 to $78.9 billion by 2025. This is a growth rate of 6.2%22. This shows the sector is growing fast. But, there are still challenges like meeting customer needs and following rules.

Advanced technologies are becoming more common, especially in aerospace and defense. These fields need precise engine parts22. New tools like 3D printing are making it possible to create complex parts with high accuracy22. CNC machining has also improved, with AI making it up to 50% more precise23.

Now, CNC machining aims for full factory automation. We already see autonomous factories23. CNC makers are also working to reduce CO2 emissions and follow green rules23. This shows a shift towards eco-friendly practices, which customers want.

On-demand manufacturing is becoming more popular, especially during global crises. It’s all about being quick and saving money23. Hybrid manufacturing, combining 3D printing and CNC, is also growing. It promises better efficiency and quality in making things23.

As these changes happen, precision engineering pros must stay flexible and keep learning. They need to focus on what customers want to succeed. The future of precision engineering will depend on innovation and meeting new market needs.

Conclusion

Precision engineering is key in changing industries by focusing on quality and accuracy. It plays a big role in making things better in many fields, like aerospace and medicine. Thanks to advanced tools like CAD/CAM systems, precision engineering has reached new heights. This has led to solutions that solve specific problems in making and designing things2425.

Precision engineering is very flexible and useful in many areas. It makes sure tools work well and last long, like those from Parmelee. They use top-notch materials and methods to make sure every tool is up to par, which makes customers happy26.

Looking ahead, precision engineering will be crucial for innovation and sustainability. As new problems come up, especially in aerospace and military, precision engineering will keep leading. It will help create efficient, safe, and effective solutions for the future2425.